When I went to Barry's to pick up the replacement quarterlight for Becky he gave me the fail sheet from when he'd put Maragret through the MoT back in June. She failed on 6 things:

1. "Offside headlamp not working on dipped beam." When I first checked the lights the offside headlight was indeed not working. I removed the plug, sprayed some Plus Gas and put the plug back in and it has been working since.

2. "Nearside windscreen wiper doesn not clear windscreen effectively." I've already dealt with this one and it works exactly as it should.

3. "Offside rear fog lamp not in good working order (not working)" When I'd checked the lights as previously mentioned the fog lights were working. I've rechecked them and they're still working.

4. "Nearside front brake pipe excessively corroded." I had a look today and I wouldn't describe it as "excessively corroded". I wirebrushed it and coated it with some grease. My local tester wouldn't just fail it if it neede cleaning. He did the same with Blue.

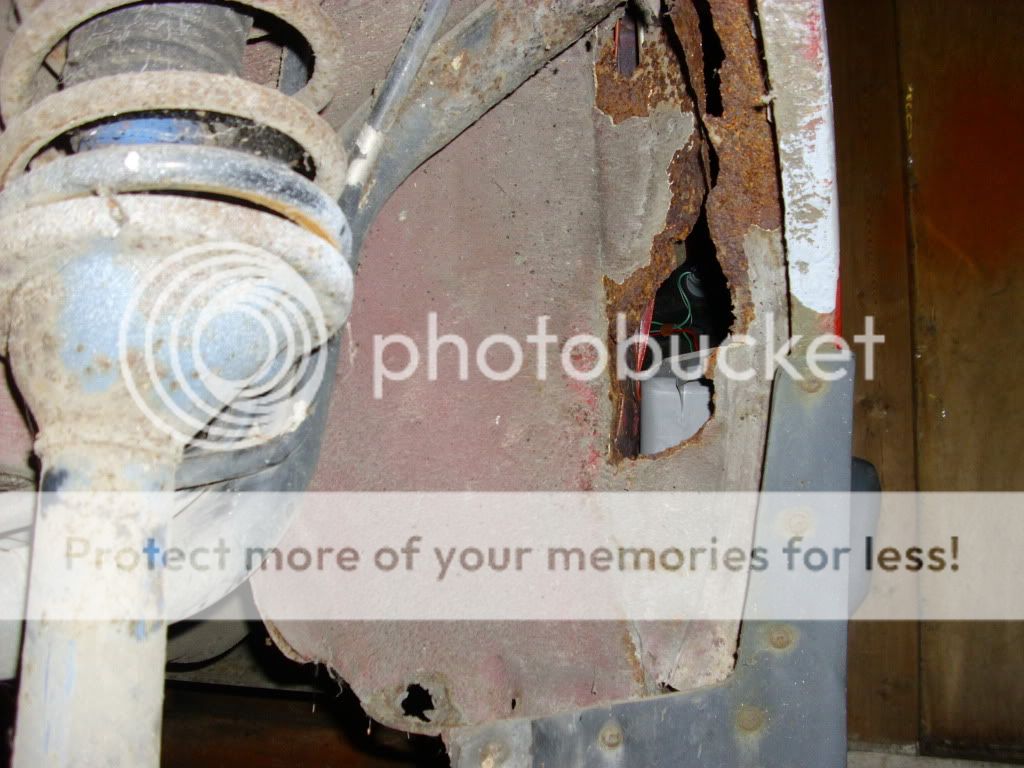

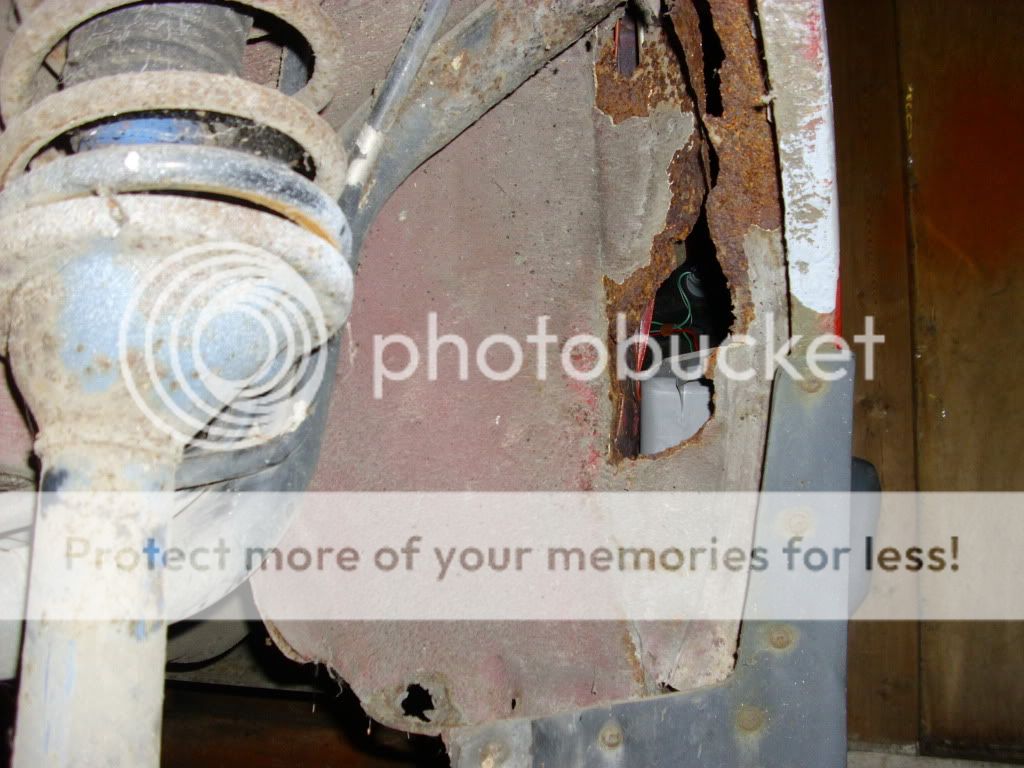

5. "Offside rear suspension component mounting prescribed area is excessively corroded." I wonder if the tester was referring to the holes in the offside sill as they're within 12 inches of the suspension mounting. I might take a closer look to see if there's any corrosion that I've missed. It'll probably be surface rust that can be wirebrushed & primed.

6. "Nearside front suspension mounting precribe area is excessively corroded." There's some rust on the turret but after wirebrushing and priming it should now be taken care of.

I wouldn't describe the rusty areas as "exessively corroded". The testing station are in the business of selling modern cars and most of the cars they test are the ones they sell. They're certainly not a classic friendly testing station. My trusty MoT tester would not fail the corrosion and would have mentioned it as an advisory so I'm quite sure that Margaret would pass without oo much trouble. Oh, and I've also changed the oil. She should run a bit better now.

Thursday, October 29, 2009

Wednesday, October 28, 2009

Nearly ready for MoT

The welding is nearly finished on Margaret. I cut out the thin steel on the other hole and welded a plate over it reusing the remains of Becky's old OS sill. The welding is nearly done now.

I managed to get the wipers working as they should. Just the glass for the driver's door mirror (on order from Champion) and Margaret will be fit for the MoT. The registration document (V5C) came in the post (despite the postal strike) so I was able to declare SORN. I took the car for a quick spin round the back roads to keep things free and once the car was back in the garage I decided to align the steering wheel so it is now straight.

I managed to get the wipers working as they should. Just the glass for the driver's door mirror (on order from Champion) and Margaret will be fit for the MoT. The registration document (V5C) came in the post (despite the postal strike) so I was able to declare SORN. I took the car for a quick spin round the back roads to keep things free and once the car was back in the garage I decided to align the steering wheel so it is now straight.

I managed to get the wipers working as they should. Just the glass for the driver's door mirror (on order from Champion) and Margaret will be fit for the MoT. The registration document (V5C) came in the post (despite the postal strike) so I was able to declare SORN. I took the car for a quick spin round the back roads to keep things free and once the car was back in the garage I decided to align the steering wheel so it is now straight.

I managed to get the wipers working as they should. Just the glass for the driver's door mirror (on order from Champion) and Margaret will be fit for the MoT. The registration document (V5C) came in the post (despite the postal strike) so I was able to declare SORN. I took the car for a quick spin round the back roads to keep things free and once the car was back in the garage I decided to align the steering wheel so it is now straight.

Thursday, October 22, 2009

Ups & downs

Starting with the down I noticed that when I was setting off to take Anita to work Becky's driver's window was open. I took a look and found out that she'd been broken into but fortunately, nothing was taken (there was nothing worth stealing) and the ignition barrel was intact. I don't know why the aireheads would want to steal this car as she looks like a shed at the moment and the interior is a tip. I suspect that hotwiring is becoming a lost art and even so, Becky's battery is flat (needs replacing anyway) and needs a jump start every time. I rang the guru and he has one in stock so I can get it replaced. The first night Becky's out of the garage and this happens! As soon as I've finished the welding on Margaret Becky's going back in the garage.

On a slightly more posititve note I made a start in welding Margaret's sill. After a couple of minutes with the grinder it looked like this.

I welded a plate on the rearmost hole but I was blowing holes in the sill even with the voltage settings on the lowest. I think the remaining steel where I've ground off the rust is too thin so blowing holes can't be avoided. Maybe I should've cut a section out. I'll look at doing that on the other section. At least it is a step in the right direction as you can see.

I welded a plate on the rearmost hole but I was blowing holes in the sill even with the voltage settings on the lowest. I think the remaining steel where I've ground off the rust is too thin so blowing holes can't be avoided. Maybe I should've cut a section out. I'll look at doing that on the other section. At least it is a step in the right direction as you can see.

I took off the wiper arms and I've found out why they were loose. The part where the spindle fits in has worn away. When I was on the phone to the Acclaim guru he said the cause was lack of regular lubrication. Becky & Blue are fine so I need to lubricate them both as soon as I can. As a fix I'm going to try to build up some weld to replace what has worn away as the entire spindle assembly is rusty.

I took off the wiper arms and I've found out why they were loose. The part where the spindle fits in has worn away. When I was on the phone to the Acclaim guru he said the cause was lack of regular lubrication. Becky & Blue are fine so I need to lubricate them both as soon as I can. As a fix I'm going to try to build up some weld to replace what has worn away as the entire spindle assembly is rusty.

On a slightly more posititve note I made a start in welding Margaret's sill. After a couple of minutes with the grinder it looked like this.

I welded a plate on the rearmost hole but I was blowing holes in the sill even with the voltage settings on the lowest. I think the remaining steel where I've ground off the rust is too thin so blowing holes can't be avoided. Maybe I should've cut a section out. I'll look at doing that on the other section. At least it is a step in the right direction as you can see.

I welded a plate on the rearmost hole but I was blowing holes in the sill even with the voltage settings on the lowest. I think the remaining steel where I've ground off the rust is too thin so blowing holes can't be avoided. Maybe I should've cut a section out. I'll look at doing that on the other section. At least it is a step in the right direction as you can see. I took off the wiper arms and I've found out why they were loose. The part where the spindle fits in has worn away. When I was on the phone to the Acclaim guru he said the cause was lack of regular lubrication. Becky & Blue are fine so I need to lubricate them both as soon as I can. As a fix I'm going to try to build up some weld to replace what has worn away as the entire spindle assembly is rusty.

I took off the wiper arms and I've found out why they were loose. The part where the spindle fits in has worn away. When I was on the phone to the Acclaim guru he said the cause was lack of regular lubrication. Becky & Blue are fine so I need to lubricate them both as soon as I can. As a fix I'm going to try to build up some weld to replace what has worn away as the entire spindle assembly is rusty.

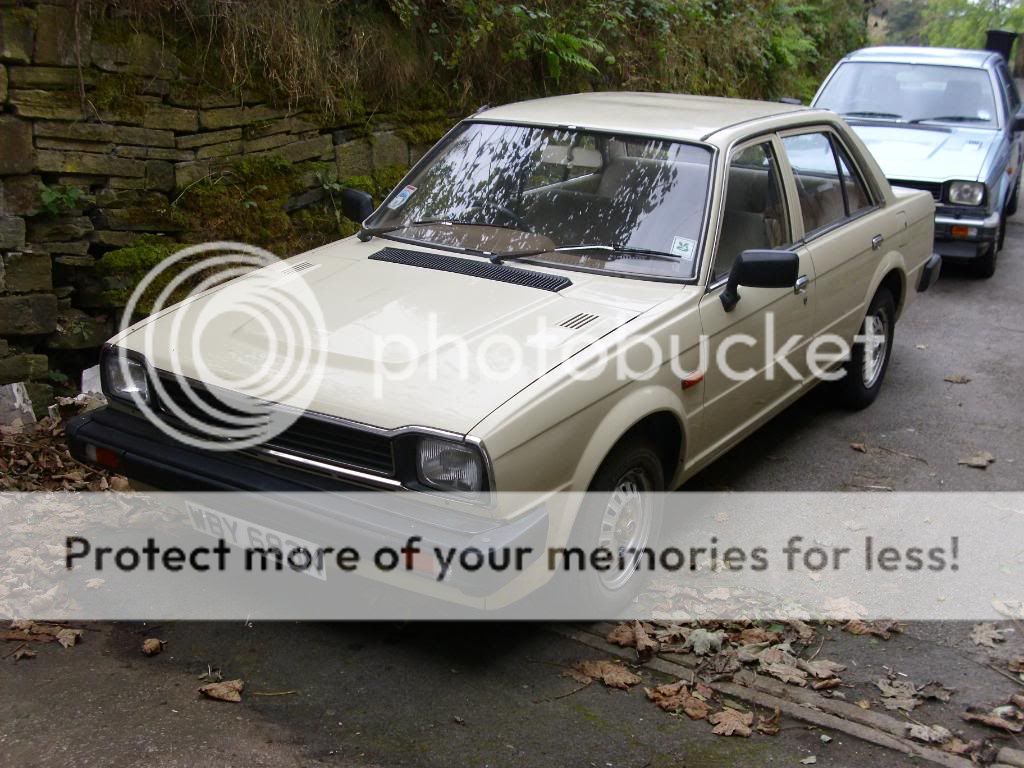

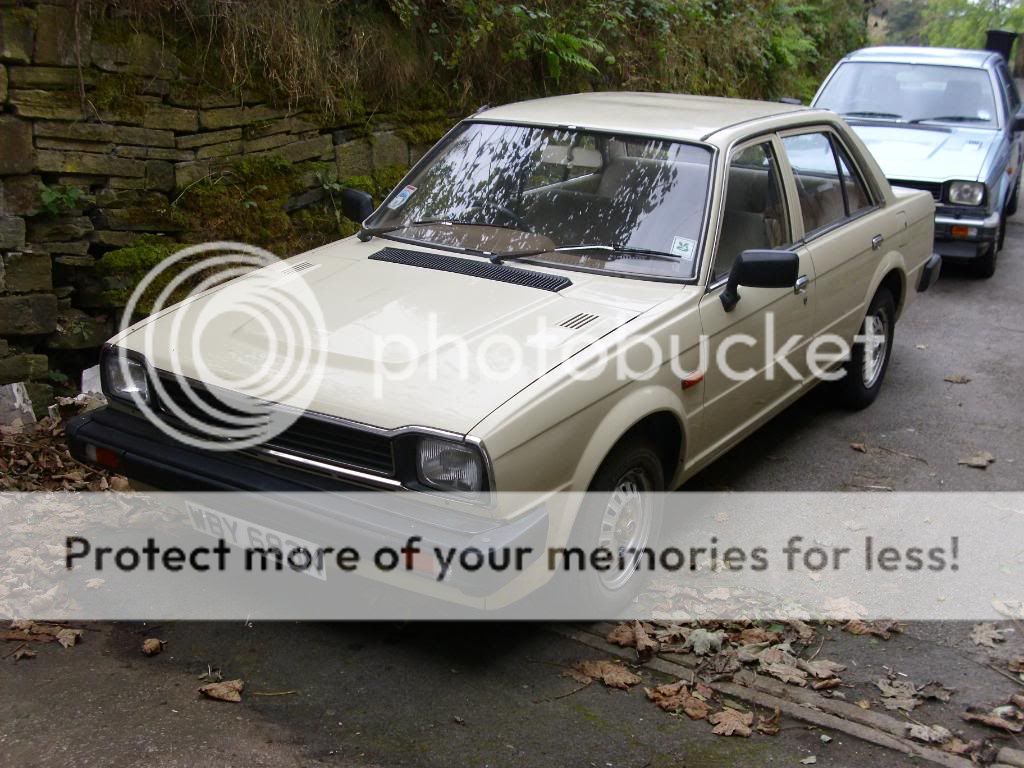

There's a guy (I'll call him Craig) who's local who has bought an Acclaim. His car is a beauty and he came round today to see my own collection. I couldn't resist the opportunity to take a photos of all 4 of our Acclaims. This must be the biggest collection of Acclaims in one place that don't belong to the guru. (even though I bought Margaret from him) Craig's car had a new exhaust as the old one was blowing and as a result of this the exhaust bracket was surplus as he'd had a later type exhaust fitted so he gave me the bracket which will go on Margaret as she has an early type exhaust. I gave him a spare parts catalogue on CD-ROM which came from the parts I got from Nick. I'm going to give him one of my spare handbooks as soon as I can find them.

Wednesday, October 21, 2009

Today I have mostly been...

...servicing a Fiesta. Anita's oldest daughter's Fiesta was in need of a service. It hasn't had any servicing done since she got the car. She got some engine oil and I went to the local motor factor to get the filters and plugs. It all went well. The last person who had replaced the air filter had written the date and mileage on it so I did the same. The car runs a lot better now.

Having to service this car meant that I had to juggle the Acclaims around in order to free up the garage to get the Fiesta in. Becky needed some fresh petrol and a tow out of the garage. (the drive slopes down to the garage) before I could jump start her. Maggie is now in the garage so I can now start plating the grot on the sill. The wipers need sorting out as they're loose. I hope the guru has some replacement parts in his extensive collection. Just lately I feel I've been losing my "mojo" but doing the Fiesta as spurred me back into action especially with Maggie in the garage where I can get some work done on her.

Blue's alternator belt had been squealing so I got a replacement for £3.50 from the local motor factor and once fitted and tensioned it was "job done" and no more squealing.

Having to service this car meant that I had to juggle the Acclaims around in order to free up the garage to get the Fiesta in. Becky needed some fresh petrol and a tow out of the garage. (the drive slopes down to the garage) before I could jump start her. Maggie is now in the garage so I can now start plating the grot on the sill. The wipers need sorting out as they're loose. I hope the guru has some replacement parts in his extensive collection. Just lately I feel I've been losing my "mojo" but doing the Fiesta as spurred me back into action especially with Maggie in the garage where I can get some work done on her.

Blue's alternator belt had been squealing so I got a replacement for £3.50 from the local motor factor and once fitted and tensioned it was "job done" and no more squealing.

Friday, October 16, 2009

An addition to the fleet

Maragret is now mine. I bought her last Friday when I got paid. It only cost me £26 to add her to my insurance. I drover her across to the garage and she didn't miss a beat so I declare her to be mechnichally sound.

I've had a quick look around and the only grot I've found are these holes in the driver's side outer sill. An easy enough job to patch even with my welding abilities.

I've had a quick look around and the only grot I've found are these holes in the driver's side outer sill. An easy enough job to patch even with my welding abilities.

There's not much else that's needed to pass the MoT. It'll certainly need less work than Becky! The car came with some service history going back to 1983 including a recent receipt for some rustproofing work which came to an eye-watering £850! No wonder that the bodywork is as good as it is. I've been going through the receipts and it appears that this car was maintained regardless of expense if the rustproofing receipt is anything to go by.

There's not much else that's needed to pass the MoT. It'll certainly need less work than Becky! The car came with some service history going back to 1983 including a recent receipt for some rustproofing work which came to an eye-watering £850! No wonder that the bodywork is as good as it is. I've been going through the receipts and it appears that this car was maintained regardless of expense if the rustproofing receipt is anything to go by.

I've had a quick look around and the only grot I've found are these holes in the driver's side outer sill. An easy enough job to patch even with my welding abilities.

I've had a quick look around and the only grot I've found are these holes in the driver's side outer sill. An easy enough job to patch even with my welding abilities. There's not much else that's needed to pass the MoT. It'll certainly need less work than Becky! The car came with some service history going back to 1983 including a recent receipt for some rustproofing work which came to an eye-watering £850! No wonder that the bodywork is as good as it is. I've been going through the receipts and it appears that this car was maintained regardless of expense if the rustproofing receipt is anything to go by.

There's not much else that's needed to pass the MoT. It'll certainly need less work than Becky! The car came with some service history going back to 1983 including a recent receipt for some rustproofing work which came to an eye-watering £850! No wonder that the bodywork is as good as it is. I've been going through the receipts and it appears that this car was maintained regardless of expense if the rustproofing receipt is anything to go by.Wednesday, October 07, 2009

This week's update

Blue wasn't warming up properly so I replaced the thermostat which cost me just short of a fiver from Champion. The head gasket set had a sealing ring for the thermostat so I was able to use that when I fitted the new thermostat. On reassembly I copper greased the bolt threads and tightened up the bolts carefully as the thermostat housing can break if the bolts are overtightened (been there and had the t-shirt) so it was torqued as per the manual. Blue now warms up as it should.

I bought a set of brake shoes for Becky (£2.99 on eBay) and when they arrived I started to fit them. While I was at it I noticed some more grot as you can see in the photo.

It has since been cleaned up with the trusty angle grinder and plates will be welded on. Why do I keep on finding more corrosion? It would've cost me an absolute fortune to pay for it to be welded. Going back to the brakes I had difficulty getting the drums back on. I found out that the handbrake linkage (which incorporates the self-adjusting mechanism) had seized solid at one end where it is supposed to pivot. Once I'd freed it off (it was the same on both sides) I was able to refit the drums and now the handbrake feels a lot better. It needs adjustment because I'd been turning the adjusting nut all the way in and it was never going to hold the way it was before I'd freed off the linkage so I need to undo the nut. As it is I can only just pull the handbrake on to the first click of the ratchet so it is too tight. I don't want to stretch or break the cables because replacing them means dropping the petrol tank to get at them.

It has since been cleaned up with the trusty angle grinder and plates will be welded on. Why do I keep on finding more corrosion? It would've cost me an absolute fortune to pay for it to be welded. Going back to the brakes I had difficulty getting the drums back on. I found out that the handbrake linkage (which incorporates the self-adjusting mechanism) had seized solid at one end where it is supposed to pivot. Once I'd freed it off (it was the same on both sides) I was able to refit the drums and now the handbrake feels a lot better. It needs adjustment because I'd been turning the adjusting nut all the way in and it was never going to hold the way it was before I'd freed off the linkage so I need to undo the nut. As it is I can only just pull the handbrake on to the first click of the ratchet so it is too tight. I don't want to stretch or break the cables because replacing them means dropping the petrol tank to get at them.

I bought a set of brake shoes for Becky (£2.99 on eBay) and when they arrived I started to fit them. While I was at it I noticed some more grot as you can see in the photo.

It has since been cleaned up with the trusty angle grinder and plates will be welded on. Why do I keep on finding more corrosion? It would've cost me an absolute fortune to pay for it to be welded. Going back to the brakes I had difficulty getting the drums back on. I found out that the handbrake linkage (which incorporates the self-adjusting mechanism) had seized solid at one end where it is supposed to pivot. Once I'd freed it off (it was the same on both sides) I was able to refit the drums and now the handbrake feels a lot better. It needs adjustment because I'd been turning the adjusting nut all the way in and it was never going to hold the way it was before I'd freed off the linkage so I need to undo the nut. As it is I can only just pull the handbrake on to the first click of the ratchet so it is too tight. I don't want to stretch or break the cables because replacing them means dropping the petrol tank to get at them.

It has since been cleaned up with the trusty angle grinder and plates will be welded on. Why do I keep on finding more corrosion? It would've cost me an absolute fortune to pay for it to be welded. Going back to the brakes I had difficulty getting the drums back on. I found out that the handbrake linkage (which incorporates the self-adjusting mechanism) had seized solid at one end where it is supposed to pivot. Once I'd freed it off (it was the same on both sides) I was able to refit the drums and now the handbrake feels a lot better. It needs adjustment because I'd been turning the adjusting nut all the way in and it was never going to hold the way it was before I'd freed off the linkage so I need to undo the nut. As it is I can only just pull the handbrake on to the first click of the ratchet so it is too tight. I don't want to stretch or break the cables because replacing them means dropping the petrol tank to get at them.

Subscribe to:

Posts (Atom)